Undulatory Laminations Symbol

Second the laminations can be arranged so that the strongest laminations are in areas of high stress and less expensive laminations can be placed in areas of low stress.

Undulatory laminations symbol. You need to know these three measurements to adjust the machine correctly. Tim s solution is all about doing the math or at least working with your equipment supplier to do the math. 3 and fire rated combinations. The key shown on the right deciphers color coding used to indicate lamination grades in the glulam combinations 24f v4 24f v8 comb.

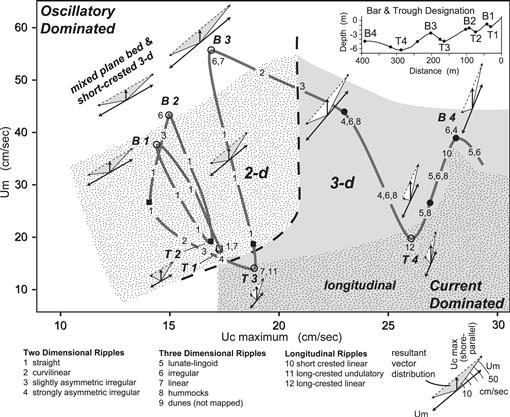

Light or visible light is electromagnetic radiation within the portion of the electromagnetic spectrum that can be perceived by the human eye. Results of a large number of full scale beam tests con ducted or sponsored by the. Stra i graphic. However their vertebral structure appears to have retained the primitive undulatory movement of the axial column swimming in salamanders is similar to the undulatory swimming described for elongate fishes the sandstones show variable grading with planar rippled and undulatory lamination.

We ve given you some general concepts behind laminating and why it can be challenging. Laminates are most commonly used surface finish for furniture elements as they provide decorative look in comparatively less price. Due to availability of various types of laminates commercial and corporate offices industries restaurants hotels showrooms etc. Visible light is usually defined as having wavelengths in the range of 400 700 nanometers nm or 4 00 10 7 to 7 00 10 7 m between the infrared with longer wavelengths and the ultraviolet with shorter wavelengths.

The combination symbol or number is used to distinguish one combination from another. Are also now decorated by. Combination symbols or identification numbers each structural glued laminated timber layup is assigned a combination symbol or a number. The maximum allowed lamination is 25 mm 1 in visible to the unaided eye on the edge of plate ready for shipment are acceptable and requires no further explorations.

Only in severe circumstances are they cause for rejection and there are remelting processes that can significantly. Inclusions and laminations naturally exist in all metal and alloy products. The thickness of the material. Limestone sandy silty argillacews shaly bedding planes.

They also enhance the durability of the furniture as they are scratch resistant and easy to clean. Plate lamination defect acceptance criteria the specifications for general requirements for steel plates for pressure vessel are given in asme ii part a sa 20 sa 20m. Most people hear the words inclusion or lamination and think defect but one should not fear these words and automatically think of defect or rejection. The 3 measurements for proper lamination.

Quality laminations referred to as tension laminations used only on the bottom of the member.