Surface Resistivity Of Copper Sheet

If the triboelectric charging of.

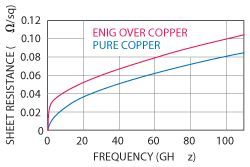

Surface resistivity of copper sheet. At one skin depth the metal s conductivity has been reduced to 36 8 of at 2 skin depths 13 5 etc. This makes the sheet resistance of 1oz copper foil about. The electrical resistivity is particularly important because it will determine its electrical performance and hence whether it is suitable for use in many electrical components. It is commonly used to characterize materials made by semiconductor doping metal deposition resistive paste printing and glass coating examples of these processes are.

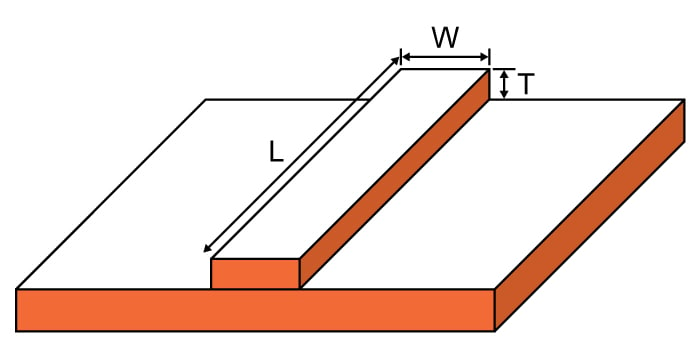

It is a measure of the lateral resistance through a thin square of material i e. Multiply the resistivity of copper by the length of the object. Sheet resistance often called sheet resistivity is a measure of resistance of thin films that are nominally uniform in thickness. The known resistivity of bulk copper is 1 68 μω cm.

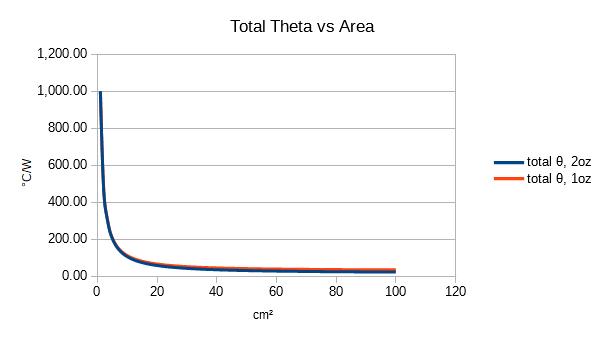

We can tell you that the resistivity of copper is 1 72x10 8 ohmmeters. This is the origin of the very simple rule of thumb that. The thickness of 1oz copper foil is about 34µm or 1 4 mils. Surface resistivity is a property of a material.

The resistance between opposite sides of a square. Sheet resistance also known as surface resistance or surface resistivity is a common electrical property used to characterise thin films of conducting and semiconducting materials. By the time you reach five skin depths the metal s conductivity is reduced to just 0 7 of its full value. Make a note of this value making sure that it has been done so in meters.

Surface resistivity ρs on the other hand is deter mined by the ratio of dc voltage u drop per unit length l to the surface current is per unit width d. The sheet resistance of 1 oz copper is 0 5 mohm sq. According to surface resistivity. ρs u l is d 2 l d u electrodes material figure 1.

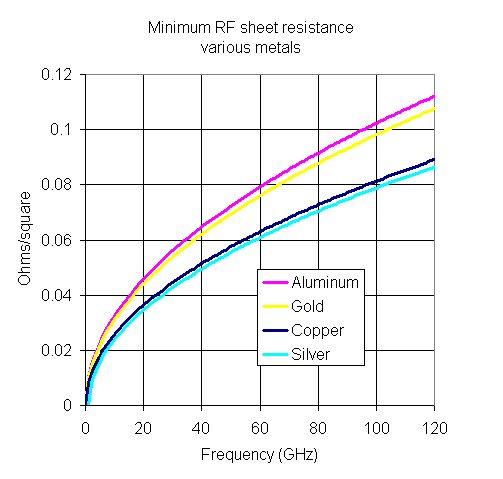

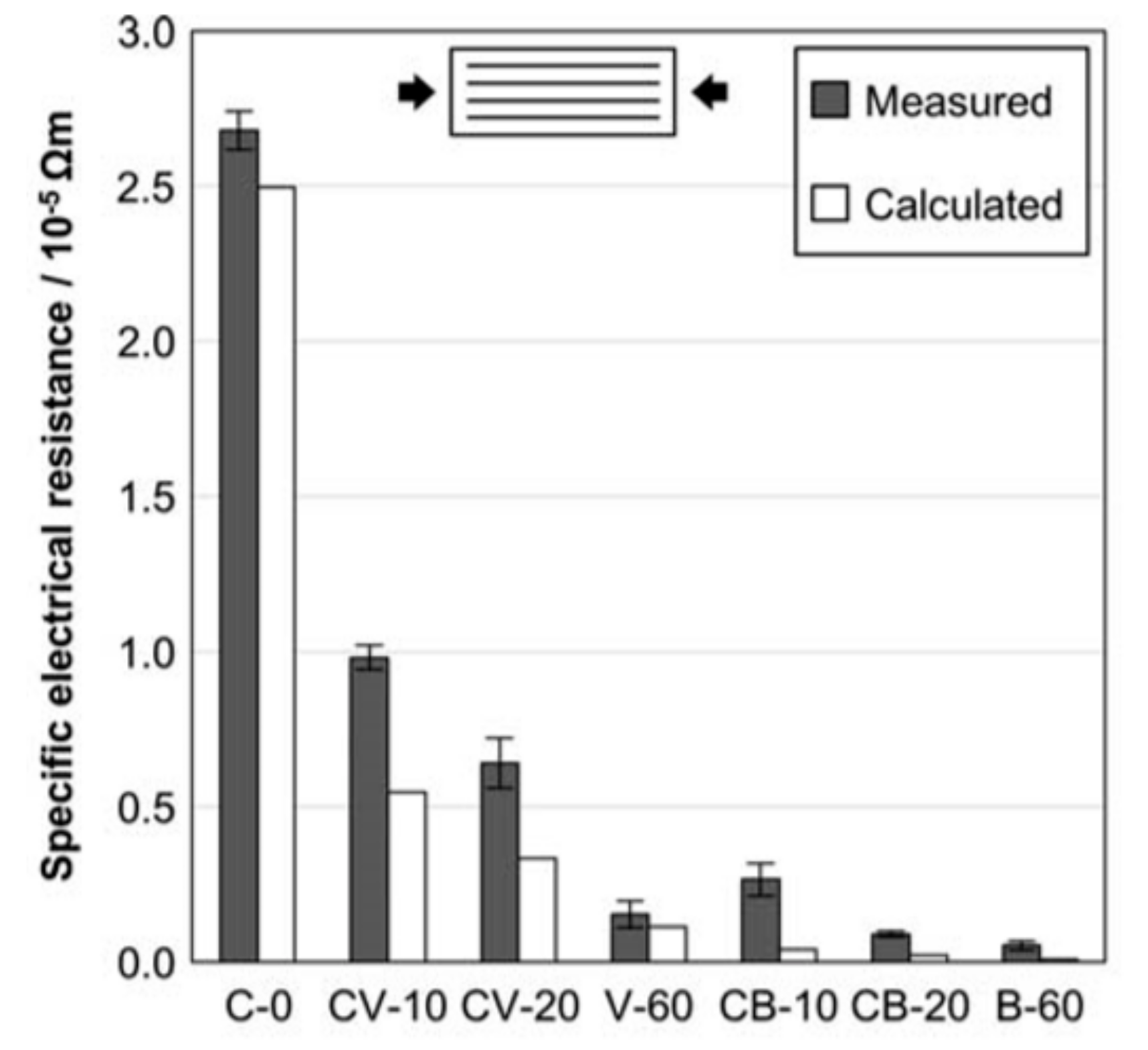

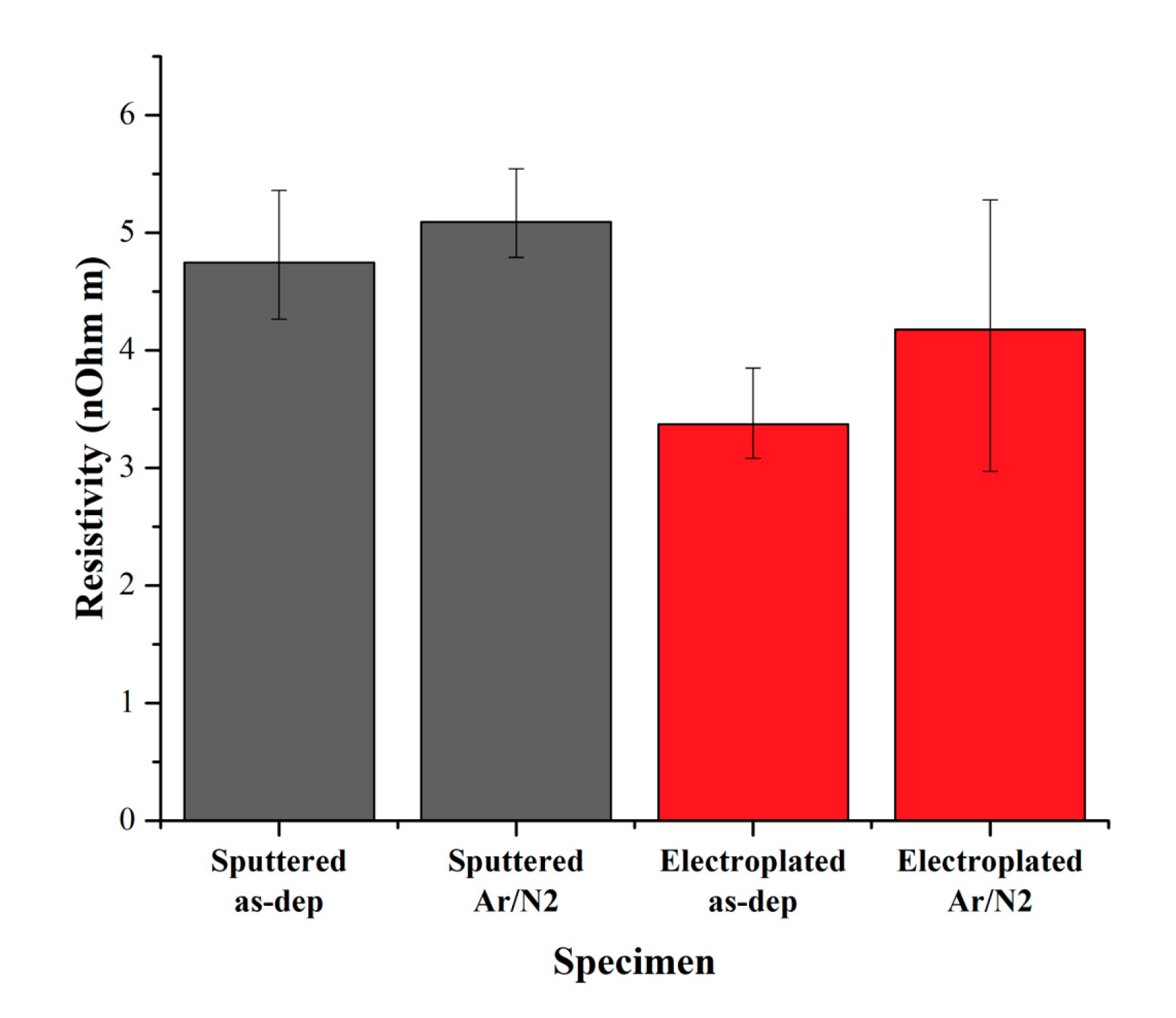

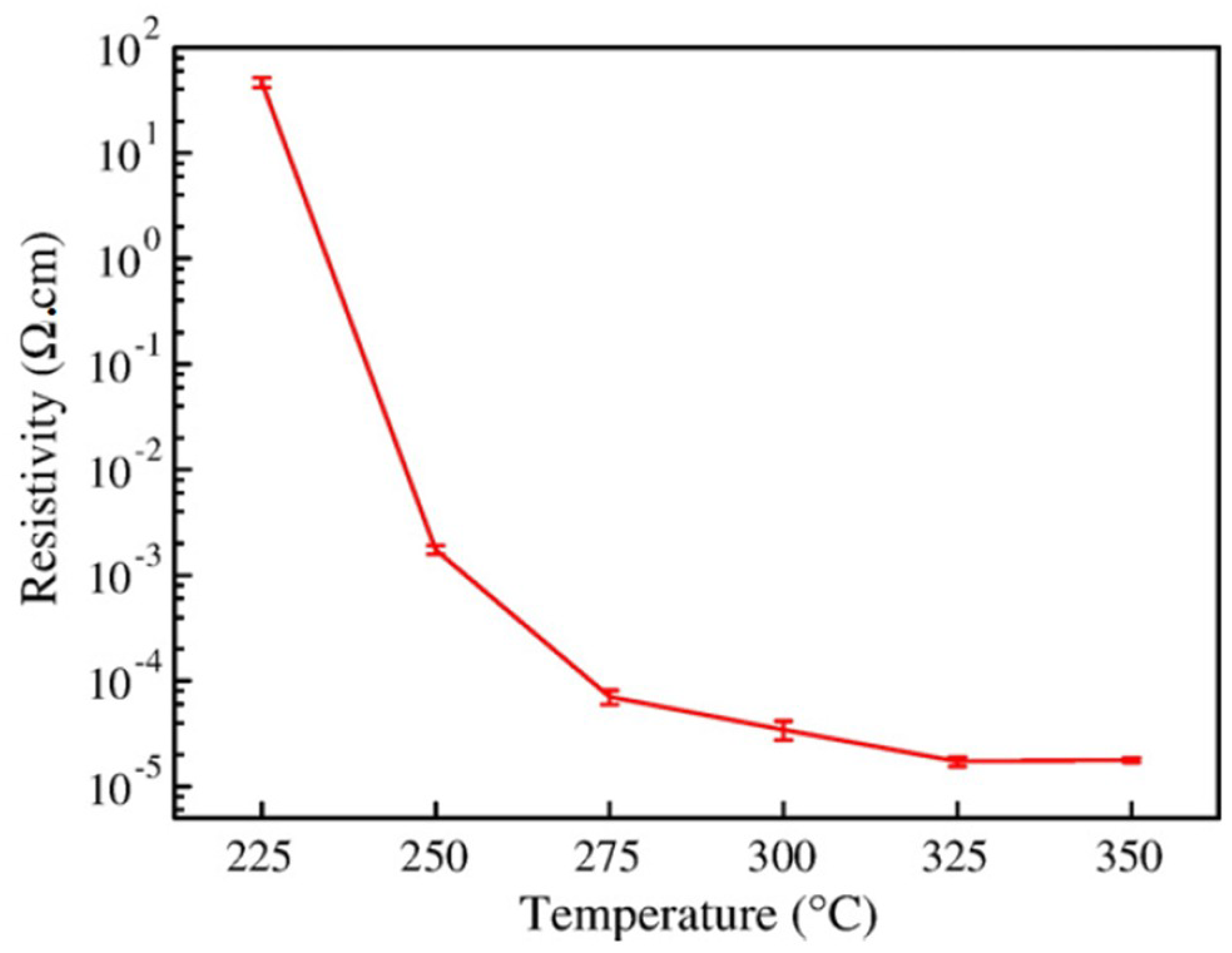

For example it will be seen that the resistivity of copper the resistivity of aluminium and that of silver and gold determines where these metals are used. A conductor copper was used as the sensing material in the first graph and an insulator ptfe was used as the sensing material in the second graph. 8 9 b where the corrected resistivity data of the deposits against plating time are illustrated the lowest resistivity of the deposits is about 0 5 μω cm which is lower than the bulk resistivity of copper. Basic setup for surface resistance and surface resistivity measurement.

The sheet resistance of 1 oz copper foil is 0 5mω square. At the surface complete conduction takes place and the resistivity of the metal is 100 of its value at dc equal to. The ipc spec for copper bulk resistivity at 20ºc is 1 72µω cm. Typically you d reference sheet resistance in terms of a material with a thickness.