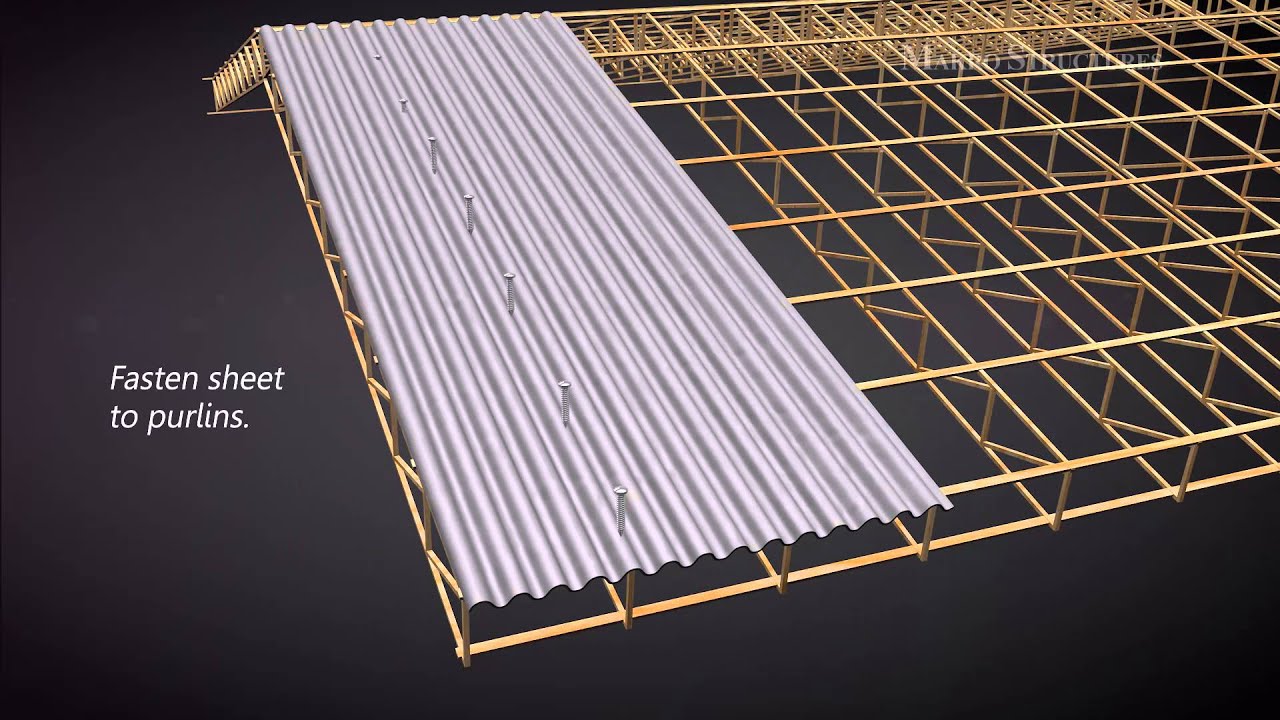

Support Spacing For Corrugated Sheets

For heavier material such as gage steel the metal roof purlins spacing length could go up to 4 feet.

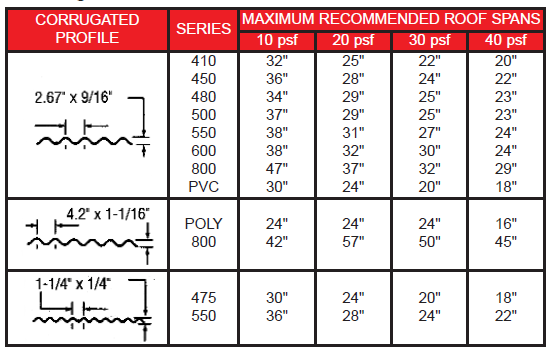

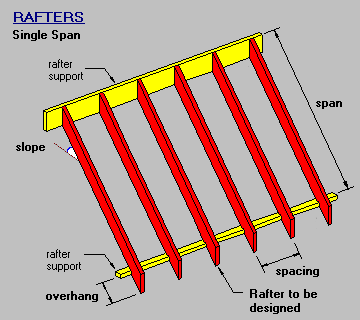

Support spacing for corrugated sheets. Subtract that number from the width of the panel and then divide by 2 to come up with the spacing for the rafters. Corrugations should run. Corrugated roofing maximum support spacing data. With pliers multi grips or a shifting spanner closed down to approximately 2mm grip the valley corrugations 20mm in from the end of the sheet and turn up as far as possible.

3 below to correspond to the design snow and or wind load pressures. Corrugated sheet roofing material is widely available and easy to use. Be careful not to tear the sheet. For the lighter material such as lightweight aluminum the common spacing length is 4 inches of clear gap.

The recommended minimum pitch for corrugated roofing is 50. These purlins or cross members are spaced a as per the chart fig. It often depends on the wideness thickness and the types of roofing materials the climate it has to withstand and many other factors.